STANDART SOĞUK ÇEKME ÇELİK KÜTÜKLER

The COLD-DRAWN PRODUCTS offered by Trafital are obtained by processing from rolls or bars. Flat and square drawn products are normally supplied with sharp edges and in their natural state, it is also possible to supply the products with specific heat treatment of stress relief, annealing, normalization and quenched and tempered condition . The commercial length of the bars is 3 or 6 m and fixed lengths can be supplied upon request. Trafital offers the possibility of supplying special profiles, rounded, rounded and shaped. The carbon steels normally available are structural or construction types, free-cutting steels and tempered steels. On request it is possible to supply the bars in other steel qualities. Some of the steels available for flat, square, round and hexagonal drawn plates: Structural or construction steels: S235JR / S275JR / S355J2 Free cutting steels: 11SMn30 / 11SMn37 / 11SMnPb30 / 11SMnPb37 Tempered steels: C45 / 39NiCrMo3 / 42CrMo4 On request it is possible to supply the drawn bars in other steel qualities.

STOKTA HAZIR BULUNANLAR VERİ SAYFALARI

S235JR (Fe 360 B, St 37, E24, ASTM A36) soğuk çekme çelik kütükler

Available profiles

LAMALAR: 4 x 2 mm’den 500 x 40 mm’ye kadar soğuk çekme lama çelik (100 mm’ye kadar kalınlık)

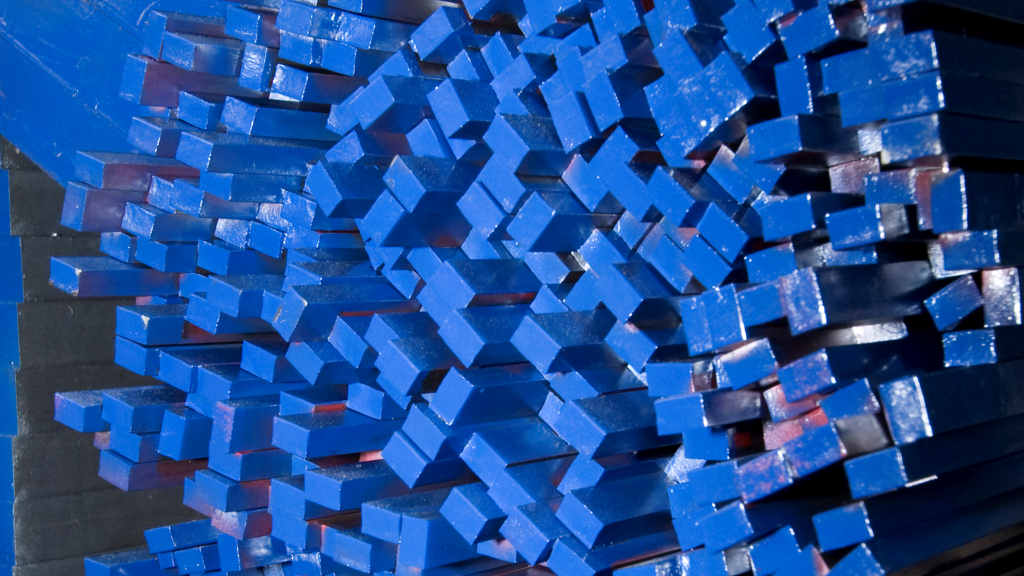

LAMALAR: 4 x 2 mm’den 500 x 40 mm’ye kadar soğuk çekme lama çelik (100 mm’ye kadar kalınlık) KARELER: 3 x 3 mm’den 150 x 150 mm’ye kadar (150 x 150 mm’nin üzerinde 250 x 250 mm’ye kadar da zımparalı)

KARELER: 3 x 3 mm’den 150 x 150 mm’ye kadar (150 x 150 mm’nin üzerinde 250 x 250 mm’ye kadar da zımparalı) YUVARLAKLAR: 2 mm’den 160 mm’ye kadar (30 mm’nin üzerinde kabuk soyulmuş ve ezilmiş de mümkün)

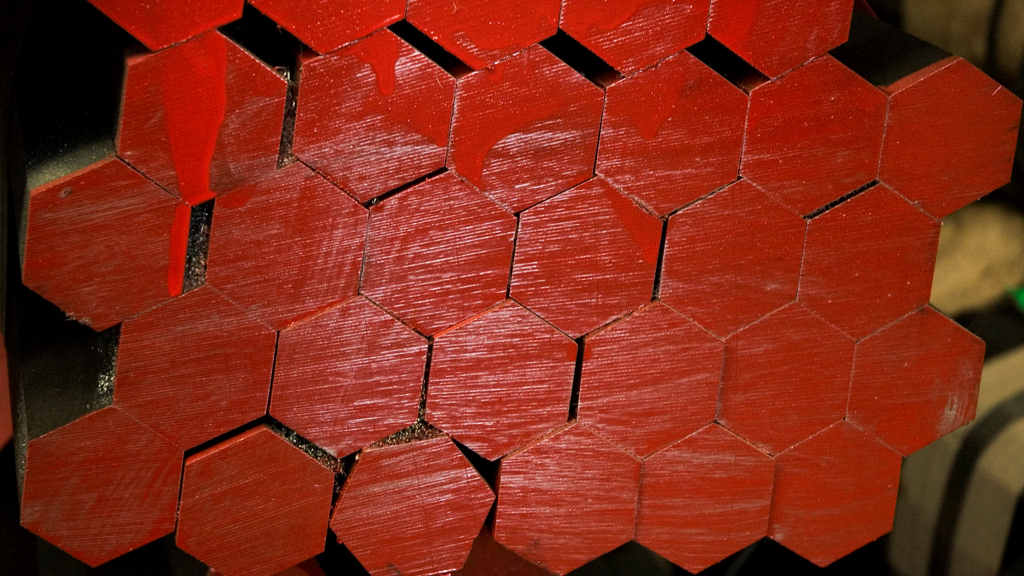

YUVARLAKLAR: 2 mm’den 160 mm’ye kadar (30 mm’nin üzerinde kabuk soyulmuş ve ezilmiş de mümkün) ALTIKÖŞELER: 4 mm’den 100 mm’ye kadar

ALTIKÖŞELER: 4 mm’den 100 mm’ye kadar KÖŞELER: 10 x 10 x 2 mm’den 100 x 100 x 100 mm’ye kadar soğuk çekme çelik köşeler

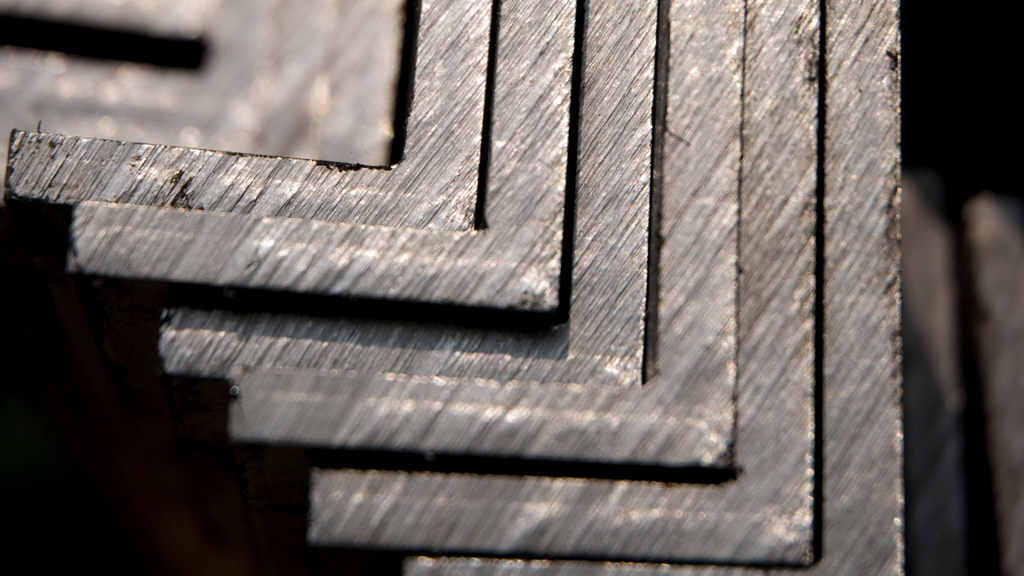

KÖŞELER: 10 x 10 x 2 mm’den 100 x 100 x 100 mm’ye kadar soğuk çekme çelik köşeler "L" KESİMLER: 25 x 15 x 3 mm’den 100 x 50 x 10 mm’ye kadar

"L" KESİMLER: 25 x 15 x 3 mm’den 100 x 50 x 10 mm’ye kadar "T" KESİMLER: 20 x 20 x 3 mm’den 79 x 79 x 9 mm’ye kadar (isteğe göre)

"T" KESİMLER: 20 x 20 x 3 mm’den 79 x 79 x 9 mm’ye kadar (isteğe göre)Specifications

Acciaio S235JR (ex Fe360 B) - Steel S235JR

COMPOSIZIONE CHIMICA - CHEMICAL COMPOSITION (EN 10277-2:2008)

| C% | Si% | Mn% | P% | S% | N% | Cu% | |

| Min | - | - | - | - | - | - | - |

| Max | 0.17 | - | 1.40 | 0.040 | 0.040 | 0.012 | 0.55 |

CARATTERISTICHE MECCANICHE TRAFILATO +C - COLD-DRAWN MECHANICAL PROPERTIES +C (EN 10277-2:2008)

| Spessore - Thickness mm. | Rp0,2 min. N/mm2 | Rm (MinMax) N/mm2 | A% Min |

| ≥5≤10 | 355 | 470840 | 8 |

| >10≤16 | 300 | 420770 | 9 |

| >16≤40 | 260 | 390730 | 10 |

| >40≤63 | 235 | 380670 | 11 |

| >63≤100 | 215 | 360640 | 11 |

C 45 (CK 45, XC 48, ASTM A29 Grade 1045) soğuk çekme çelik kütükler

Available profiles

LAMALAR: 8 x 7 mm’den 250 x 30 mm’ye kadar soğuk çekme lama çelik

LAMALAR: 8 x 7 mm’den 250 x 30 mm’ye kadar soğuk çekme lama çelik KARELER: 5 x 5 mm’den 130 x 130 mm’ye kadar (130 x 130 mm’nin üzerinde 250 x 250 mm’ye kadar da zımparalı)

KARELER: 5 x 5 mm’den 130 x 130 mm’ye kadar (130 x 130 mm’nin üzerinde 250 x 250 mm’ye kadar da zımparalı) YUVARLAKLAR: 2 mm’den 160 mm’ye kadar (20 mm’nin üzerinde kabuk soyulmuş ve ezilmiş de mümkün)

YUVARLAKLAR: 2 mm’den 160 mm’ye kadar (20 mm’nin üzerinde kabuk soyulmuş ve ezilmiş de mümkün) ALTIKÖŞELER: 6 mm’den 100 mm’ye kadar

ALTIKÖŞELER: 6 mm’den 100 mm’ye kadar YİVLİ MİLLER: 14 x 11 mm’den 48 x 42 mm’ye kadar çelik yivli miller

YİVLİ MİLLER: 14 x 11 mm’den 48 x 42 mm’ye kadar çelik yivli millerSpecifications

Acciaio C45 - Steel C45

COMPOSIZIONE CHIMICA - CHEMICAL COMPOSITION (EN 10083-2:2006)

| C% | Si% | Mn% | P% | S% | Cr% | Mo% | Ni% | Cr+Mo+Ni% | |

| Min | 0.42 | - | 0.50 | - | - | - | - | - | - |

| Max | 0.50 | 0.40 | 0.80 | 0.045 | 0.045 | 0.40 | 0.10 | 0.40 | 0.63 |

CARATTERISTICHE MECCANICHE TRAFILATO +C - COLD-DRAWN MECHANICAL PROPERTIES +C (EN 10277-5:2008)

| Spessore - Thickness mm. | Rp0,2 min. N/mm2 | Rm (MinMax) N/mm2 | A% Min |

| ≥5≤10 | 565 | 7501050 | 5 |

| >10≤16 | 500 | 7101030 | 6 |

| >16≤40 | 410 | 6501000 | 7 |

| >40≤63 | 360 | 630900 | 8 |

| >63 | 310 | 580850 | 8 |

C 45 (CK 45, XC 48, ASTM A29 Grade 1045) Kamalar için soğuk çekme çelik kütükler (DIN 6880)

Available profiles

LAMALAR: 8 x 7 mm’den 100 x 50 mm’ye kadar soğuk çekme lama çelik (h9 x h11 toleransı)

LAMALAR: 8 x 7 mm’den 100 x 50 mm’ye kadar soğuk çekme lama çelik (h9 x h11 toleransı) KARELER: 6 x 6 mm’den 90 x 90 mm’ye kadar (h9 x h9 toleransı)

KARELER: 6 x 6 mm’den 90 x 90 mm’ye kadar (h9 x h9 toleransı)Specifications

Acciaio C45 - Steel C45

COMPOSIZIONE CHIMICA - CHEMICAL COMPOSITION (EN 10083-2:2006)

| C% | Si% | Mn% | P% | S% | Cr% | Mo% | Ni% | Cr+Mo+Ni% | |

| Min | 0.42 | - | 0.50 | - | - | - | - | - | - |

| Max | 0.50 | 0.40 | 0.80 | 0.045 | 0.045 | 0.40 | 0.10 | 0.40 | 0.63 |

CARATTERISTICHE MECCANICHE TRAFILATO +C - COLD-DRAWN MECHANICAL PROPERTIES +C (EN 10277-5:2008)

| Spessore - Thickness mm. | Rp0,2 min. N/mm2 | Rm (MinMax) N/mm2 | A% Min |

| ≥5≤10 | 565 | 7501050 | 5 |

| >10≤16 | 500 | 7101030 | 6 |

| >16≤40 | 410 | 6501000 | 7 |

| >40≤63 | 360 | 630900 | 8 |

| >63 | 310 | 580850 | 8 |

39 Ni Cr Mo 3 / 42 Cr Mo 4 sertleştirilmiş ve tavlanmış soğuk çekme alaşımlı çelik kütükler

Specifications

Acciaio 39 Ni Cr Mo 3 - Steel 39 Ni Cr Mo 3

COMPOSIZIONE CHIMICA - CHEMICAL COMPOSITION (EN 10277-5:2008)

| C% | Si% | Mn% | P% | S% | Cr% | Mo% | Ni% | |

| Min | 0.35 | - | 0.50 | - | - | 0.60 | 0.15 | 0.70 |

| Max | 0.43 | 0.40 | 0.80 | 0.025 | 0.035 | 1.00 | 0.25 | 1.00 |

CARATTERISTICHE MECCANICHE LAMINATO ALLO STATO BONIFICATO +AR+QT - HOT ROLLED MECHANICAL PROPERTIES +AR+QT (EN 10083-3:2006)

| Diametro - Diameter mm. |

Spessore - Thickness mm. |

Rp 0,2 min. N/mm2 |

Rm (MinMax) N/mm2 |

A% Min |

KV Min J |

Z% Min |

| ≤16 | ≤8 | 785 | 9801180 | 11 | - | 40 |

| >16≤40 | >8≤20 | 735 | 9301130 | 11 | 35 | 40 |

| >40≤100 | >20≤60 | 685 | 8801080 | 12 | 40 | 45 |

| >100≤160 | >60≤100 | 635 | 830980 | 12 | 40 | 50 |

| >160≤250 | >100≤160 | 540 | 740880 | 13 | 40 | 50 |

Acciaio 42 Cr Mo 4 - Steel 42 Cr Mo 4

COMPOSIZIONE CHIMICA - CHEMICAL COMPOSITION (EN 10083-3:2006)

| C% | Si% | Mn% | P% | S% | Cr% | Mo% | |

| Min | 0.38 | - | 0.60 | - | - | 0.90 | 0.15 |

| Max | 0.45 | 0.40 | 0.90 | 0.025 | 0.035 | 1.20 | 0.30 |

CARATTERISTICHE MECCANICHE LAMINATO ALLO STATO BONIFICATO +AR+QT - HOT ROLLED MECHANICAL PROPERTIES +AR+QT (EN 10083-3:2006)

| Diametro - Diameter mm. |

Spessore - Thickness mm. |

Rp 0,2 min. N/mm2 |

Rm (MinMax) N/mm2 |

A% Min |

KV Min J |

Z% Min |

| ≤16 | ≤8 | 900 | 11001300 | 10 | - | 40 |

| >16≤40 | >8≤20 | 750 | 10001200 | 11 | 35 | 45 |

| >40≤100 | >20≤60 | 650 | 9001100 | 12 | 35 | 50 |

| >100≤160 | >60≤100 | 550 | 800950 | 13 | 35 | 50 |

| >160≤250 | >100≤160 | 500 | 750900 | 14 | 35 | 55 |

Download Trafital-39NiCrMo3.pdf Download Trafital-42CrMo4.pdf

Müşterinin isteğine göre ayrıca üretebildiklerimiz:

- Müşteri’nin çizimine göre soğuk çekme çelik özel kesimler

- Yuvarlak köşeli kare ya da lama soğuk çekme kütükler

- Kremayer üretimi için uygun, ısıl işlemli soğuk çekme çelik kütükler

- Ekstra boyutlar